Page 9 - American Punch Ironworker Tooling Catalog

P. 9

PUNCHING TIPS

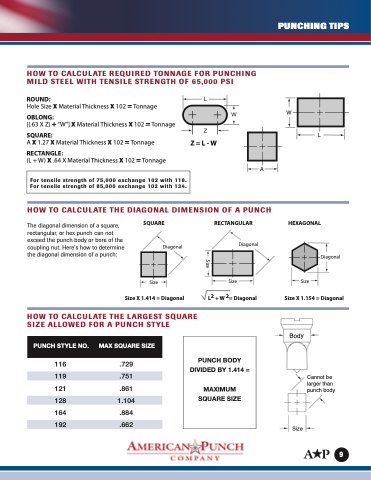

HOW TO TO CALCULATE REQUIRED TONNAGE FOR PUNCHING MILDSTEELWITHTENSILESTRENGTHOF65 000PSI

Z = L - W ROUND:

Hole Size X X Material Thickness X X 102 = Tonnage OBLONG:

W L [( 63 X X X Z) + “W”] X X X Material Thickness X X X 102 = Tonnage SQUARE:

For For tensile tensile strength strength of of 85 000 000 exchange exchange 102 102 with with 134 A A X X X 1 1 27 X X X Material Thickness X X X 102 =Tonnage RECTANGLE:

(L + W) X X X 64 X X X Material Thickness X X X 102 = Tonnage For For tensile tensile strength strength of of 75 000 000 exchange exchange 102 102 with with 118 A HOW TO CALCULATE THE DIAGONAL DIMENSION OF A A A A A PUNCH The diagonal dimension of a a a a square rectangular or hex punch can not exceed the the punch body or or bore of the the coupling nut Here’s how to determine the diagonal dimension of a a a punch:

SQUARE Diagonal

Size Size X 1 1 414 = Diagonal

RECTANGULAR

Diagonal

Size L2 + W 2= Diagonal

HEXAGONAL

Diagonal

Size X 1 1 154 = Diagonal

Size HOW TO CALCULATE THE LARGEST SQUARE SIZE ALLOWED FOR A A A A A PUNCH STYLE

PUNCH STYLE

NO MAX SQUARE SIZE 116 729 119 751 121 861 128 1 1 1 104 164 884 192 662

Body

PUNCH BODY DIVIDED BY 1 1 414 = MAXIMUM SQUARE SIZE Cannot be larger than punch body Size 9 Size