Page 6 - American Punch Ironworker Tooling Catalog

P. 6

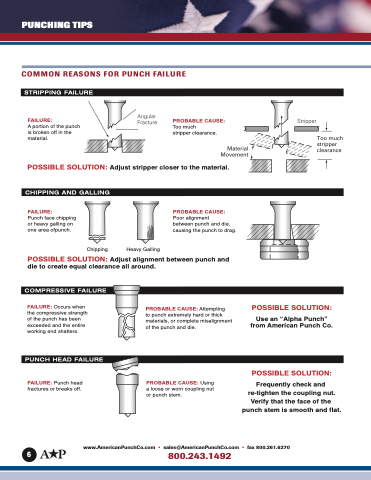

PUNCHING TIPS

COMMON REASONS FOR PUNCH FAILURE

STRIPPING FAILURE

FAILURE: A A portion of of the the punch is broken off in the the material PROBABLE CAUSE: Too much

stripper clearance POSSIBLE SOLUTION:

Adjust stripper closer to the material CHIPPING AND GALLING

FAILURE: Punch face chipping or heavy galling on on one area ofpunch Chipping

PROBABLE CAUSE: Poor alignment

between punch punch and

die causing the punch punch to drag Heavy Galling

POSSIBLE SOLUTION:

Adjust alignment

between punch and

die to create equal clearance all around COMPRESSIVE FAILURE

FAILURE: Occurs when the the compressive strength of the the the punch has been exceeded and

the the entire working end shatters PUNCH HEAD FAILURE

PROBABLE CAUSE: Attempting

to punch extremely hard or or thick materials or or complete misalignment of the punch and

die PROBABLE CAUSE: Using a loose or or or worn coupling nut

or or or punch stem POSSIBLE SOLUTION:

Use an an “Alpha Punch” from American Punch Punch Co POSSIBLE SOLUTION:

Frequently check and

re-tighten the the the coupling nut

Verify that the the the face of the the the punch stem is smooth and

flat FAILURE: Punch head fractures or breaks off RINGING

6 FAILURE: Material being punched is www AmericanPunchCo AmericanPunchCo com com • • sales@AmericanPunchCo com com • • fax 800 800 261 6270 800 243 1492

PROBABLE CAUSE: POSSIBLE SOLUTION:

Material is thicker